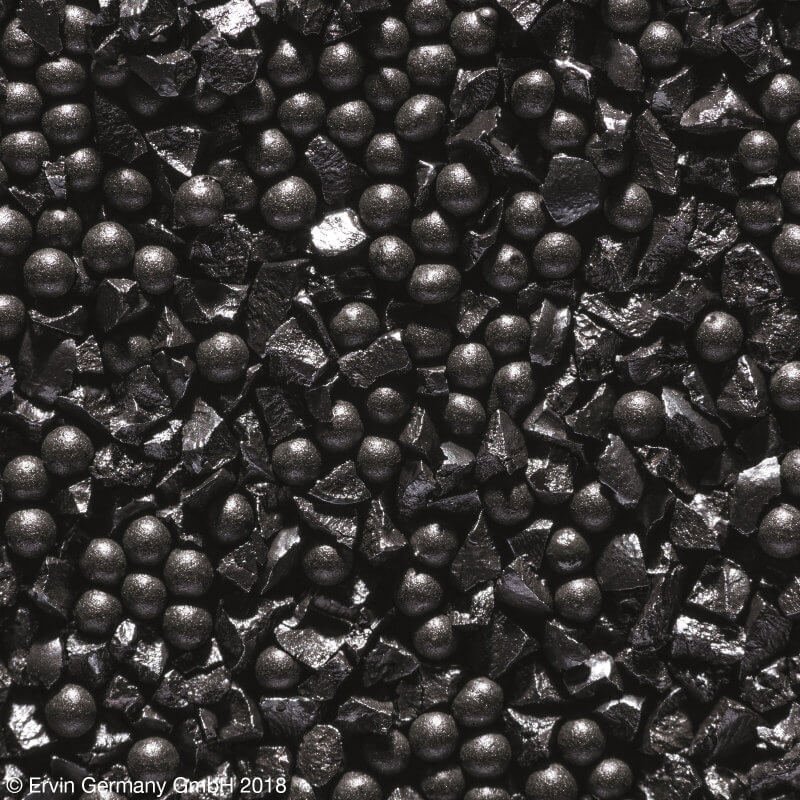

Blasting agent

Ervin technology for high carbon cast steel abrasives as well as for stainless steel abrasives is world leading.

- Quality:

- AMASTEEL® | AMACAST® | AMACHROME® | AMAGRIT® | AMAPEEN® | AMACUT®

-

Various qualities

Cast steel abrasives & stainless steel abrasives for various applications.

Lowest consumption

Lowest consumption, highest productivity, and lowest costs.

Radiant power

Uniform blasting performance as well as low system wear.

Properties

Ervin technology for high carbon cast steel abrasives as well as for stainless steel abrasives is world leading. Ervin produces in Glaubitz (Germany) according to international SAE specifications. Extensive quality control combined with state-of-the-art technology in the manufacturing process guarantees the highest durability and cleaning performance.

The various qualities AMASTEEL®, AMACAST®, AMACHROME®, AMAGRIT®, AMAPEEN® and AMACUT® cover diverse advantages and areas of application. The advantages and application examples of the individual qualities can be found under Technical details.

Advantages

- Lowest consumption

- Highest productivity, lowest costs

- Uniform jet power

- Low system wear

- Rust-free and clean surfaces

- Local technical service

- Cast steel abrasives as well as stainless steel abrasives

- Various qualities: AMASTEEL®, AMACAST®, AMACHROME®, AMAGRIT®, AMAPEEN® and AMACUT®.

- Various areas of application (depending on quality)

Technical details

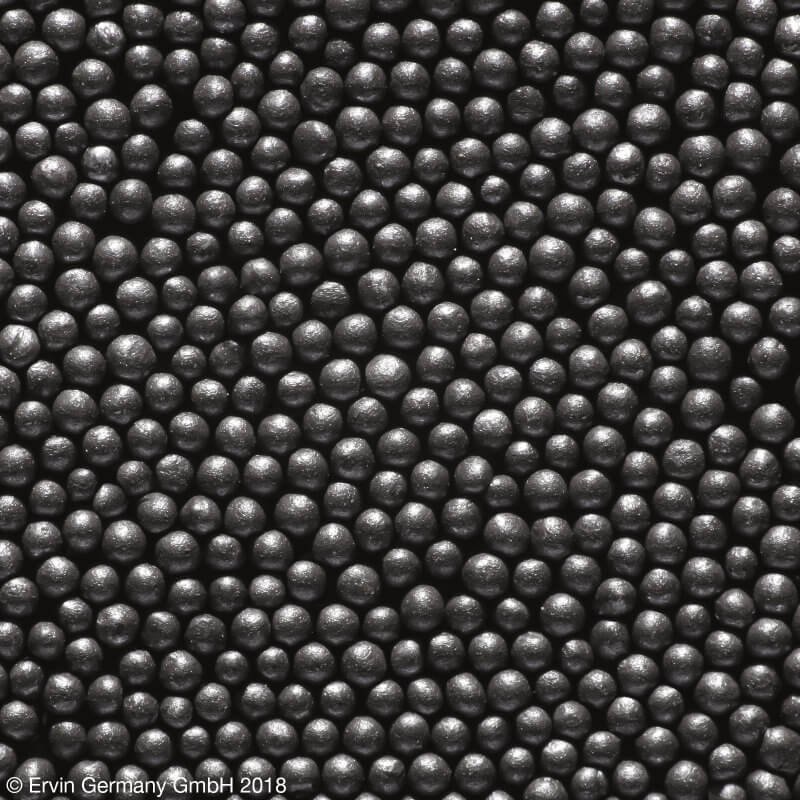

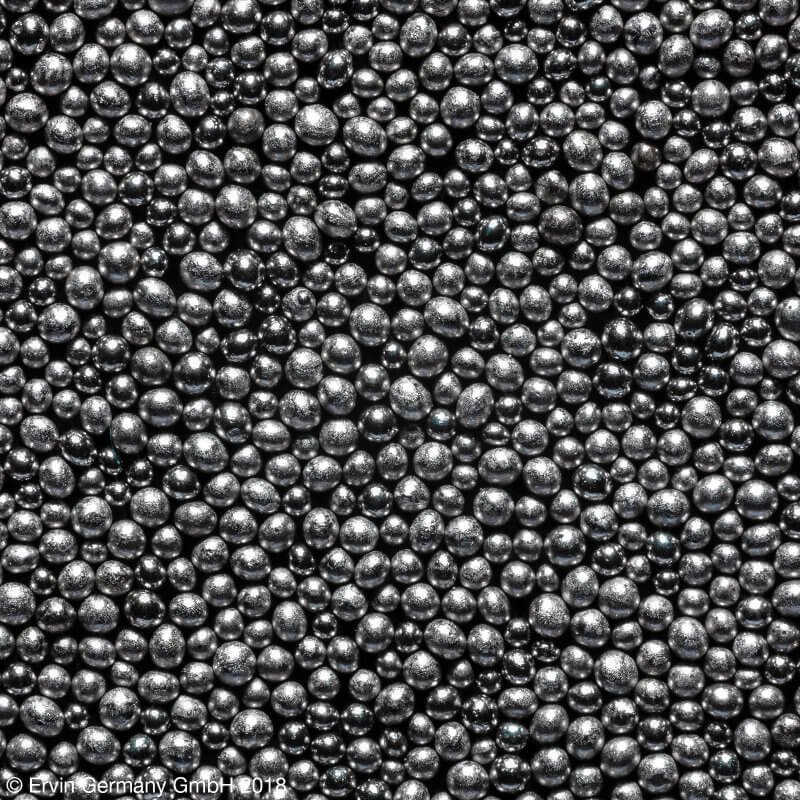

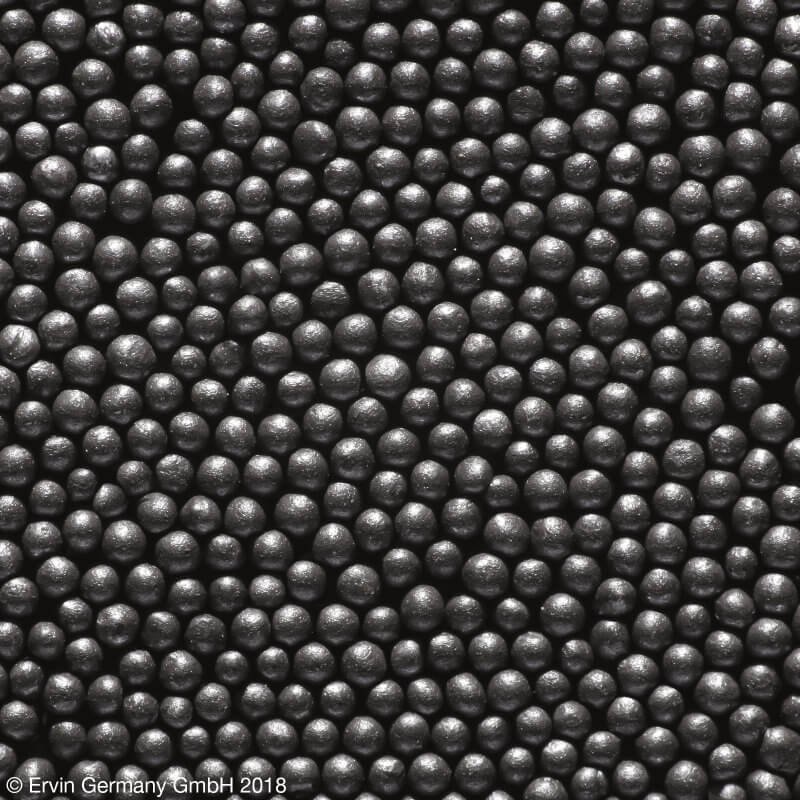

AMASTEEL®

AMASTEEL is a high quality abrasive with a martensitic microstructure.

Suitable for

- Blast wheel Blast applications

- Compressed air and injector jet applications

- Desanding, derusting & descaling

- Surface pretreatment

- Shot peening

- Stone cuttingAdvantages

- Lowest consumption

- Highest productivity, lowest costs

- Uniform jet power

- Low system wear

- Less dust and waste

- Technical serviceApplication examples

- Foundries and forges

- Metallurgy

- Vehicle construction

- Energy sector

- Mechanical engineering

- Steel construction

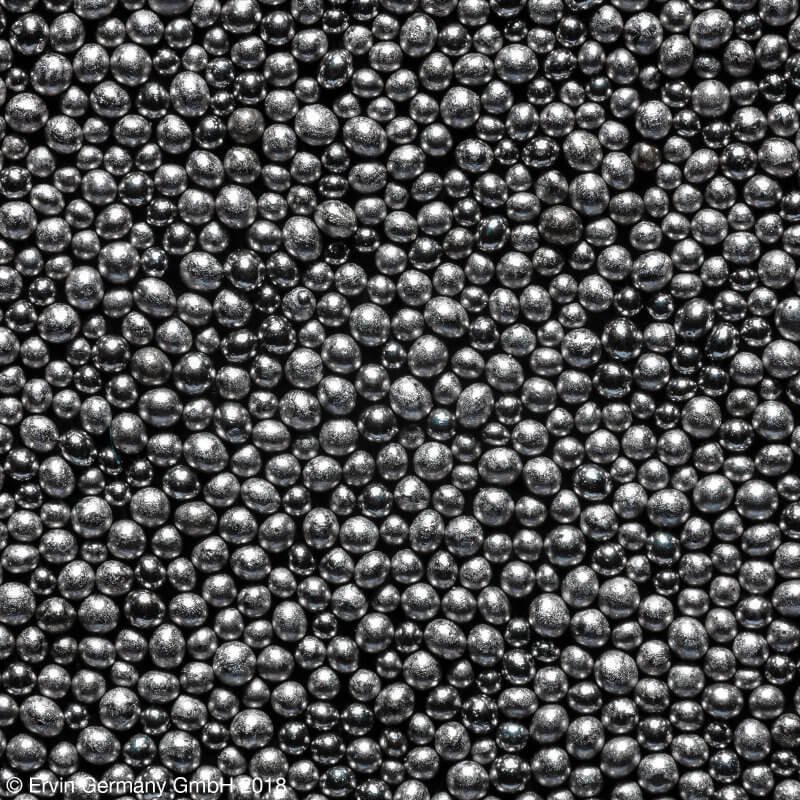

AMACAST®

AMACAST is manufactured in Tecumseh (USA) using a process that was developed in the aerospace industry and is unique in the entire abrasives industry. This uniqueness, combined with the high level of expertise of the team in Sprockhövel (Germany), makes AMACAST a particularly high-quality austenitic abrasive.

Suitable for

- spinning wheel systems

- Compressed air blasting systems

- Surface preparation

- Surface cleaning

- Surface finishingAdvantages

- Lowest consumption

- Highest productivity, lowest costs

- Highest roundness (min. 95 %)

- High gloss surfaces

- Less wear

- Rust-free and clean surfaces

- Local technical serviceApplication examples

- Aluminium and zinc die casting

- Stainless steel casting

- Welded stainless steel constructions (mechanical engineering)

- Aluminium and stainless steel profiles

- Aluminium, brass and stainless steel forgings

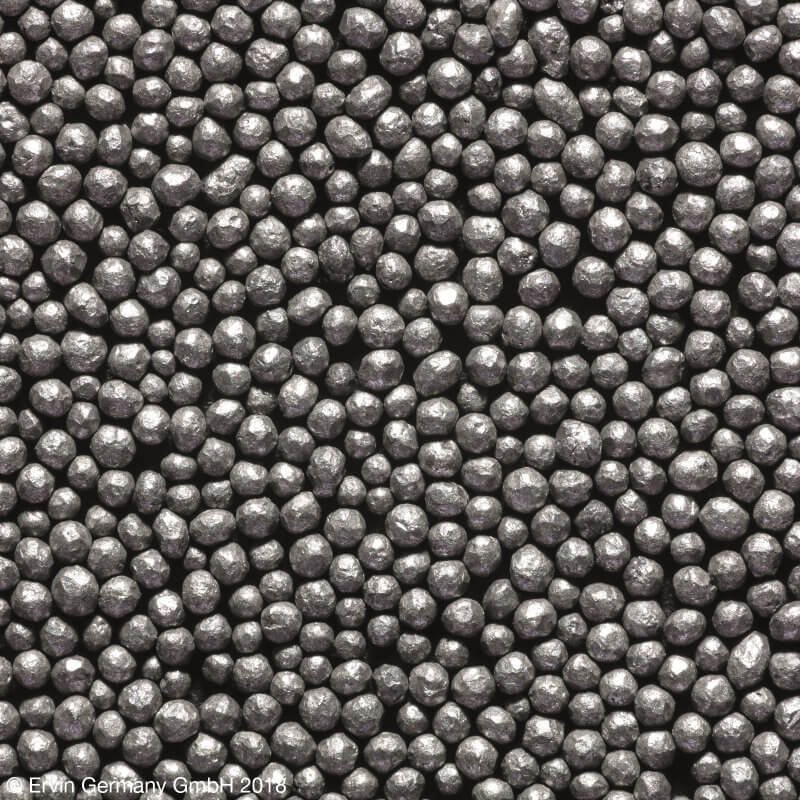

AMACHROME®

Production in Sprockhövel (Germany), combined with the know-how of our own technology centre in Tecumseh (USA), make AMACHROME one of the highest quality round ferritic stainless steel abrasives.

Suitable for

- spinning wheel systems

- Compressed air blasting systems

- Surface preparation

- Surface cleaning

- Surface finishingAdvantages

- Highest durability

- Lowest consumption

- Highest productivity, lowest costs

- Less wear and tear on the system

- Rust-free and clean surfaces

- Local technical serviceApplication examples

- Aluminium and zinc die casting

- Aluminium profiles

- Granite, natural stone and concrete block

- Aluminium, brass and stainless steel forgings

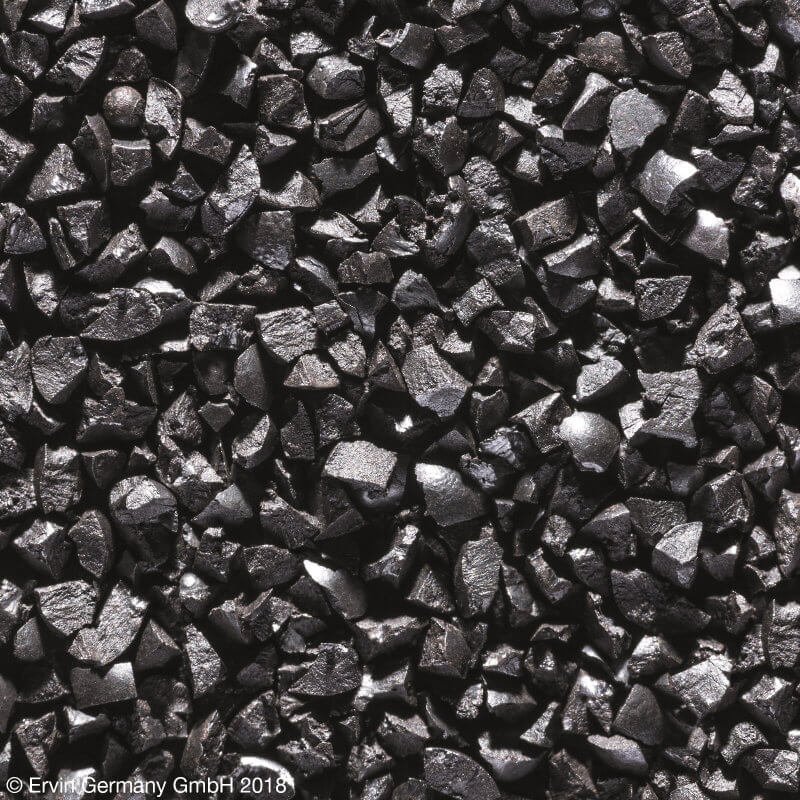

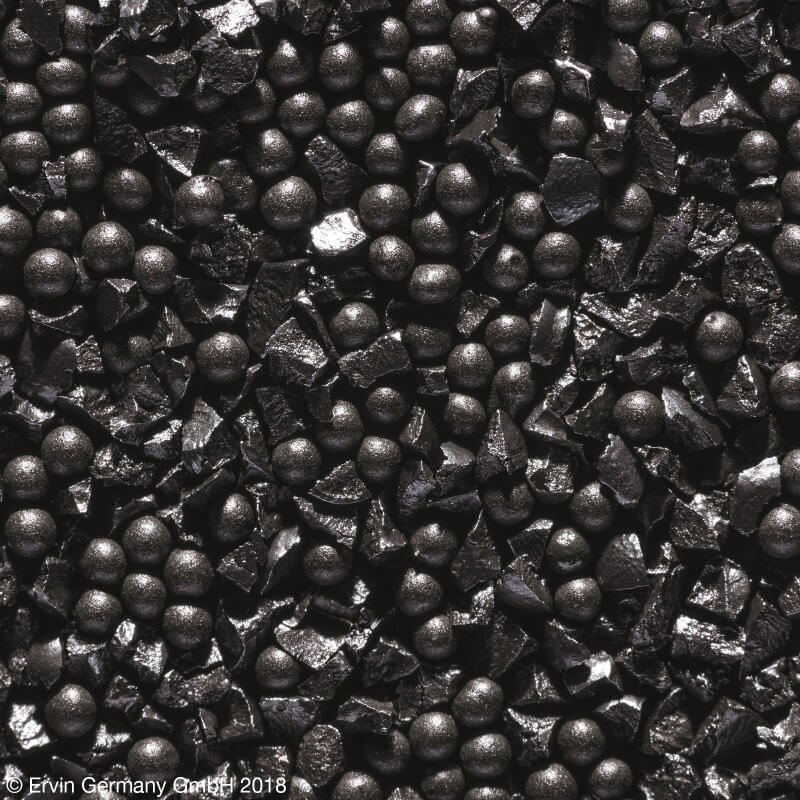

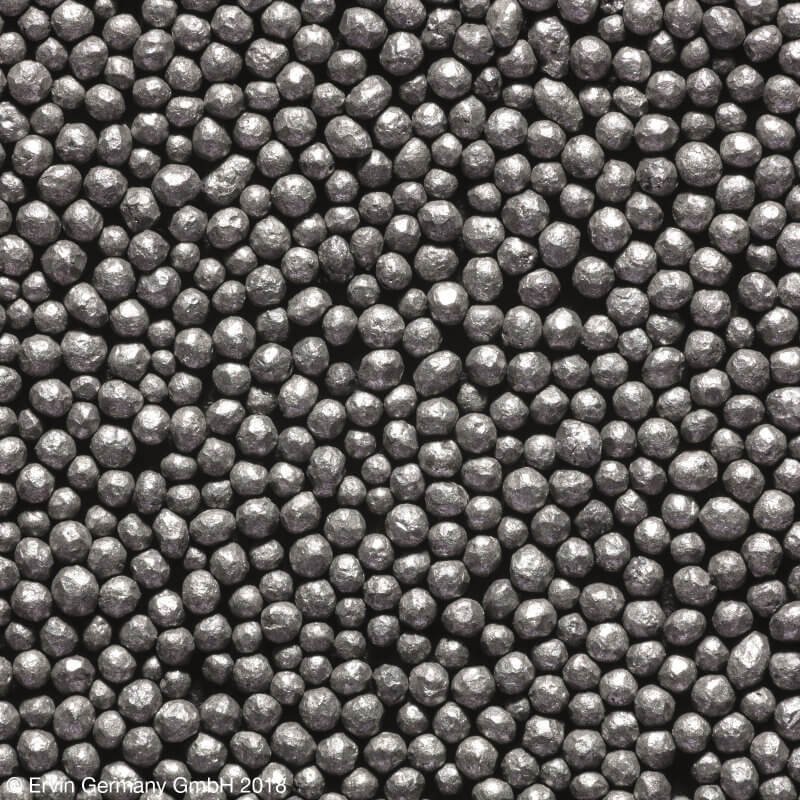

AMAGRIT®

Production in Sprockhövel (Germany), combined with the know-how of our own technology centre in Tecumseh (USA), make AMAGRIT one of the highest quality edged stainless steel abrasives.

Suitable for

- Compressed air blasting systems and blast wheel systems

- Compressed air blasting systems

- Surface preparation for coating/painting

- Surface cleaning

- Replacing mineral blasting media such as corundum, glass beads, etc.Advantages

- Lowest consumption

- Highest productivity, lowest costs

- Significant savings compared to mineral abrasives

- Less dust and waste

- Rust-free and clean surfaces

- Local technical serviceApplication examples

- Welded stainless steel constructions (mechanical engineering)

- Granite, natural stone and concrete block

- Aluminium profiles before coating/painting

- Stainless steel forgings

AMAPEEN®

The production according to SAE and AMS specifications in Glaubitz makes AMAPEEN a particularly high-quality martensitic shot peening abrasive.

Suitable for

- Blast wheel Blast applications

- Compressed air and injector jet applications

- Shot peeningAdvantages

- Lowest consumption

- Highest productivity, lowest costs

- Uniform jet power

- Low system wear

- Less dust and waste

- Technical serviceApplication examples

- Aerospace

- Automotive

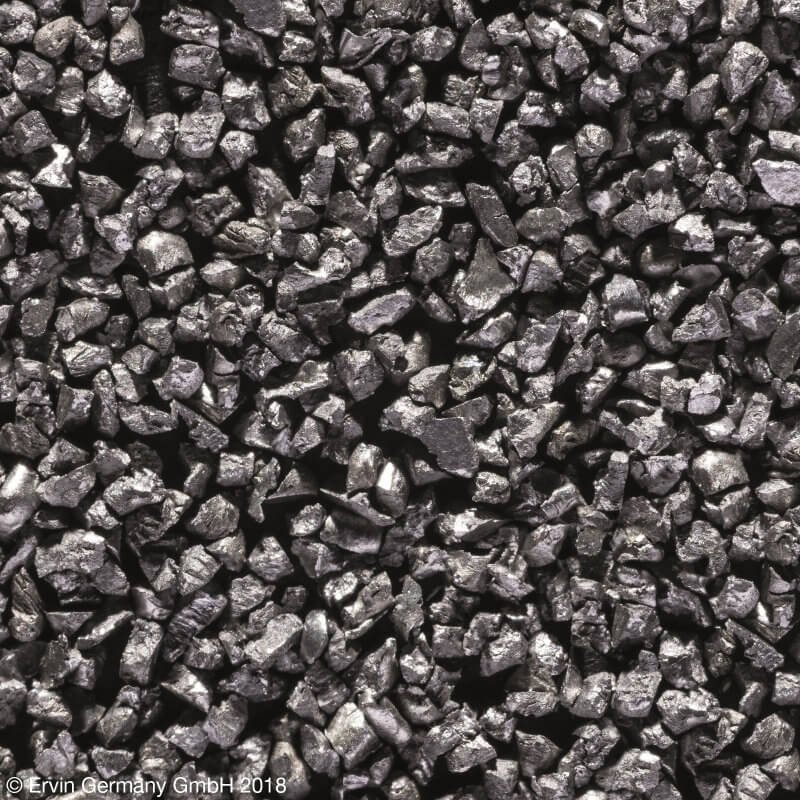

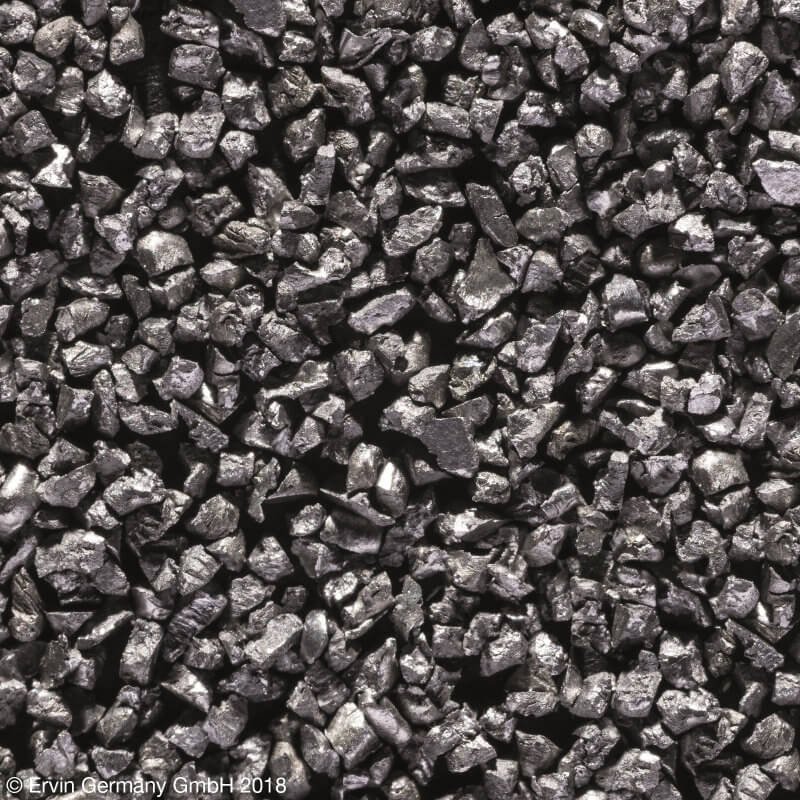

AMACUT®

The unique manufacturing process in Glaubitz (Germany) makes AMACUT a particularly high-quality martensitic grit abrasive.

Suitable for

- Log band saws

- CuttingAdvantages

- Lowest consumption

- Highest productivity, lowest costs

- Uniform grinding performance

- Less dust and waste

- Technical serviceApplication examples

- Stone cutting

-

Gasser GmbH

Gasser - Handel mit Gießerei- und Stahlwerksbedarf Gesellschaft m.b.H. has been active as a company since 1925. Over time, various commercial agencies and products produced under their own brand were added. Today, the company concentrates 100% on products for iron and non-iron foundries and manufacturers and processors. Since 2017, the company has been part of the SENN Group and has also been based in Erl since 2022.

Since 2018, the company has been certified according to ISO9001, currently according to the 2015 revision of the standard.