Saffil® | Polycrystalline Mats

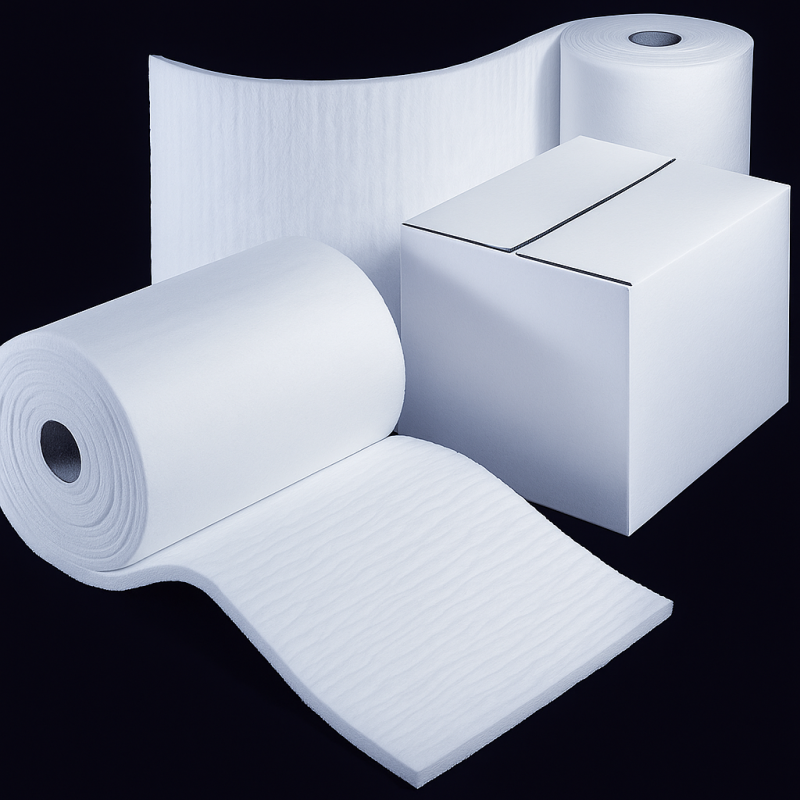

Saffil mats are light, flexible mats needled with polypropylene threads made from high-purity polycrystalline wool.

- Thickness (mm)

- 13mm 25mm

- Density / volume weight (kg / m³)

- 96 kg / m³

-

Temperature resistance

High temperature resistance up to 1600 ° C.

Tensile strenght

High tensile strength and resilience.

Thermal conductivity

Low thermal conductivity.

PRODUCT TYPE

Mats (blankets) made of high temperature wool are needled lightweight mats and provide an effective solution for a wide range of thermal insulation applications. They are characterized by excellent insulating properties, high resistance to chemicals, elasticity and dimensional stability. They are exclusively inorganic and therefore do not generate smoke or fumes when exposed to heat. They are available in a wide range of densities and thickness combinations, making them one of the most versatile product groups on the market.

MATERIAL

Polycrystalline wool (PCW Poly Crystalline Wool) consist of fibers with a very high alumina content (Al2O3 > 70% by weight %). They are produced from aqueous spinning solutions using the “sol-gel process”. During the subsequent heat treatment, the previously produced, water-soluble green fibers crystallize. Polycrystalline wools are generally used at operating temperatures> 1300 ° C or, in the case of critical chemical and physical application conditions, also at lower temperatures. The first production of polycrystalline wool can be traced back to the 1970s.

UNIFRAX®

Unifrax® is one of the world's leading manufacturers of high-performance specialty fibers and inorganic materials that are used in industry, the automotive sector and fire protection. Our goals, philosophy and values build on our efforts to manufacture high quality products that help our customers save energy, reduce pollution and improve fire protection.

Product variations

MoreRoll goods

Fiber mats are sold as roll goods as standard. The roll length depends on the selected thickness. As a standard width, we have 610mm wide rolls from stock. Double widths are available on request.

More

MoreMoldings

We manufacture molded parts according to your specifications. The roll goods are made using

Water jet

Punching

Plotting

brought into the right shape for you.

More

MoreFiber modules

We manufacture fiber modules according to customer specifications that are designed for the insulation requirements of industrial ovens, kilns and heating devices.

TECHNICAL DETAILS

Chemical Analysis Al2O3: 95,0 – 97,0 SiO2: 3,0 – 5,0 Other: <0,5 Physical Properties Colour: White Classification temperature (° C): 1600 Specific heat at 1000 ° C (J / KgK) 1000 Density (kg / m3) 96 Mean fiber diameter (μm) 3 – 4 Permanent linear shrinkage (%) after 24 hours 1500 °C: <4 CHARACTERISTICS

Saffil mats are light, flexible mats needled with polypropylene threads made from high-purity polycrystalline wool. The polypropylene threads allow a higher strength and flexibility of the mat. The temperature resistance is up to 1600 ° C. Saffil mats can be used in a wide variety of applications. They are particularly suitable for applications where shot (melt beads) are not desired or where resistance to corrosion is important.

Benefits

- High temperature resistance (up to 1600 ° C)

- Low thermal conductivity

- no visible shot

- Thermal shock resistance & durability

to chemicals - High tensile strength and resilience

- insoluble in water

- suitable for facings and anchor modules

-

Downloads

Saffil mat data sheet

Product properties, typical applications and availabilities.

-

Gasser GmbH

Gasser - Handel mit Gießerei- und Stahlwerksbedarf Gesellschaft m.b.H. has been active as a company since 1925. Over time, various commercial agencies and products produced under their own brand were added. Today, the company concentrates 100% on products for iron and non-iron foundries and manufacturers and processors. Since 2017, the company has been part of the SENN Group and has also been based in Erl since 2022.

Since 2018, the company has been certified according to ISO9001, currently according to the 2015 revision of the standard.