Tap hole cone

Vacuum-formed refractory shapes / tap hole cones

At KS we serve several parts used in the casting process of aluminum rods and aluminum alloys.

- PRODUCT VARIATIONS

- Manufacture according to customer specifications

-

Tap hole cone

- Tap hole cones act as a plug to regulate the flow of molten metal from furnaces and ladles, in the casting process of aluminum rods and aluminum alloys.

- They have proper hardness and toughness, not fragile or peel off.

- Cup caps are produced in large quantities by the vacuum suction filter molding process, mixed with specially selected inorganic and organic binders.

Features

- Excellent insulating properties

- High feed efficiency

- High strength/weight ratio

- Good thermal shock resistance

- Low thermal conductivity and thermal mass

- Low heat

- Low smoke

- Non-stick aluminum

- Formulations range from hard molds to very flexible molds with good recovery properties and can be based on ceramic fibers, biosoluble fibers, or mineral fibers. This process is mainly used for round or conical molds.

- They are produced in different densities, specifications, patterns, and performance to meet the most demanding thermal requirements of our customers.

Cost-oriented

Technically excellent and cost-oriented solution.

Qualities

Various designs and qualities available.

Refractory

Depending on the material, application temperatures up to 1300°C.

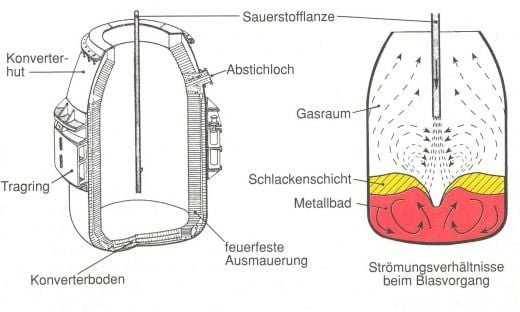

An opening at the bottom of the cupola at the cupola heart through which the molten iron can flow out of the furnace via a channel. The tap hole is plugged with a plug after each charge during periodic melting and is pierced again during the next tapping.

Advantages

It has the advantages of lightweight, high-temperature resistance, good thermal stability, low thermal conductivity, small specific heat, and mechanical vibration resistance.

Technical support

- Tap hole cones are suitable for mechanical or manual operations.

- We are ready to support you and propose the best solutions to your problems.

Customized solutions

- Custom shapes in various hardness grades are available on request.

-

Gasser GmbH

Gasser - Handel mit Gießerei- und Stahlwerksbedarf Gesellschaft m.b.H. has been active as a company since 1925. Over time, various commercial agencies and products produced under their own brand were added. Today, the company concentrates 100% on products for iron and non-iron foundries and manufacturers and processors. Since 2017, the company has been part of the SENN Group and has also been based in Erl since 2022.

Since 2018, the company has been certified according to ISO9001, currently according to the 2015 revision of the standard.