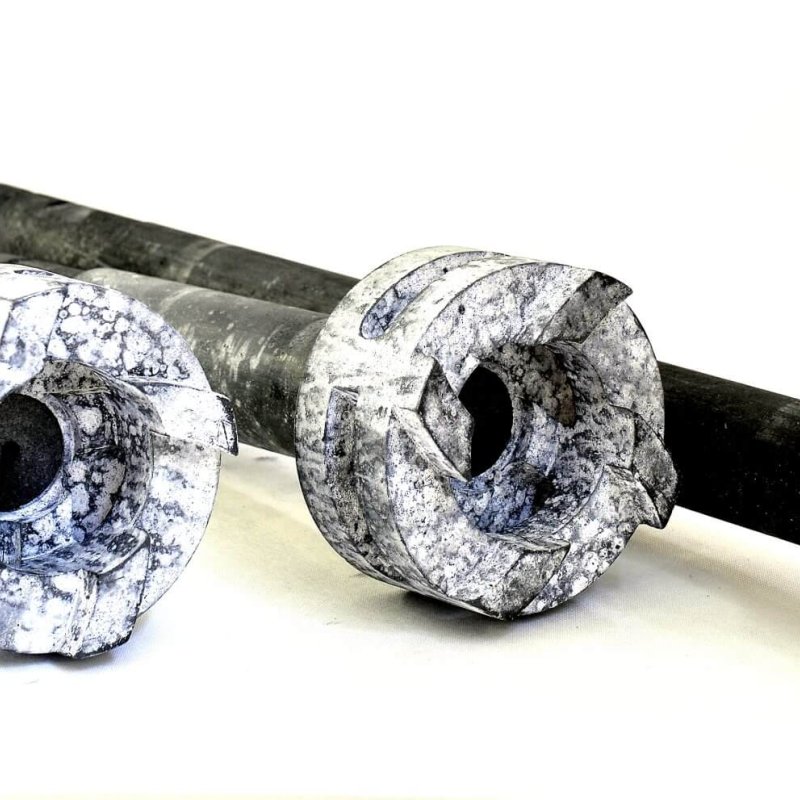

Blower powder (exothermic)

The cavity powders specially developed for the aluminum industry are available ready-to-use and are applied over the entire area of the feeder (s) after the liquid metal has been poured.

-

-

Gasser GmbH

Gasser - Handel mit Gießerei- und Stahlwerksbedarf Gesellschaft m.b.H. has been active as a company since 1925. Over time, various commercial agencies and products produced under their own brand were added. Today, the company concentrates 100% on products for iron and non-iron foundries and manufacturers and processors. Since 2017, the company has been part of the SENN Group and has also been based in Erl since 2022.

Since 2018, the company has been certified according to ISO9001, currently according to the 2015 revision of the standard.